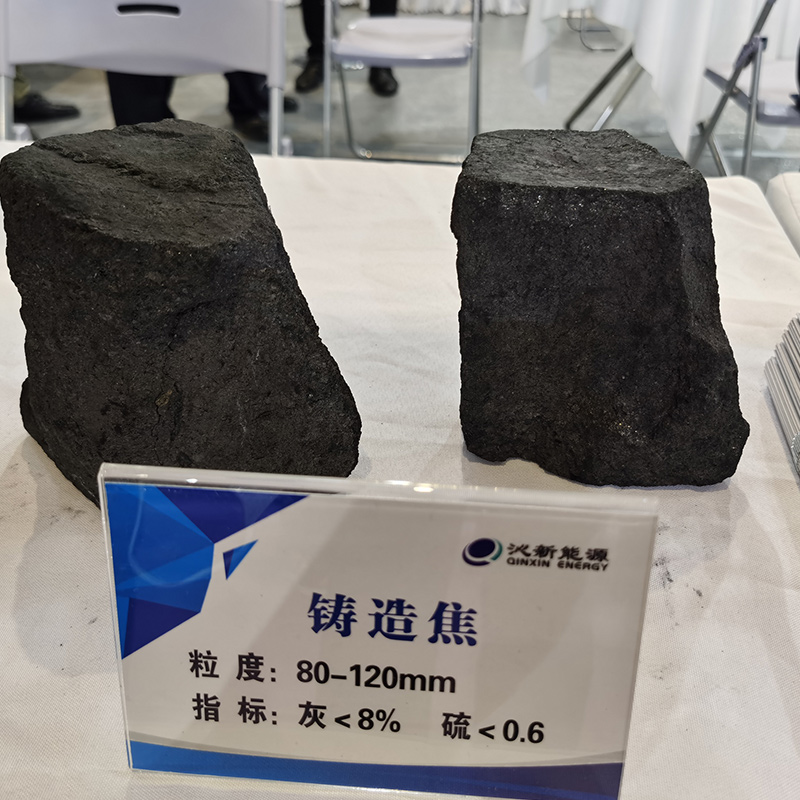

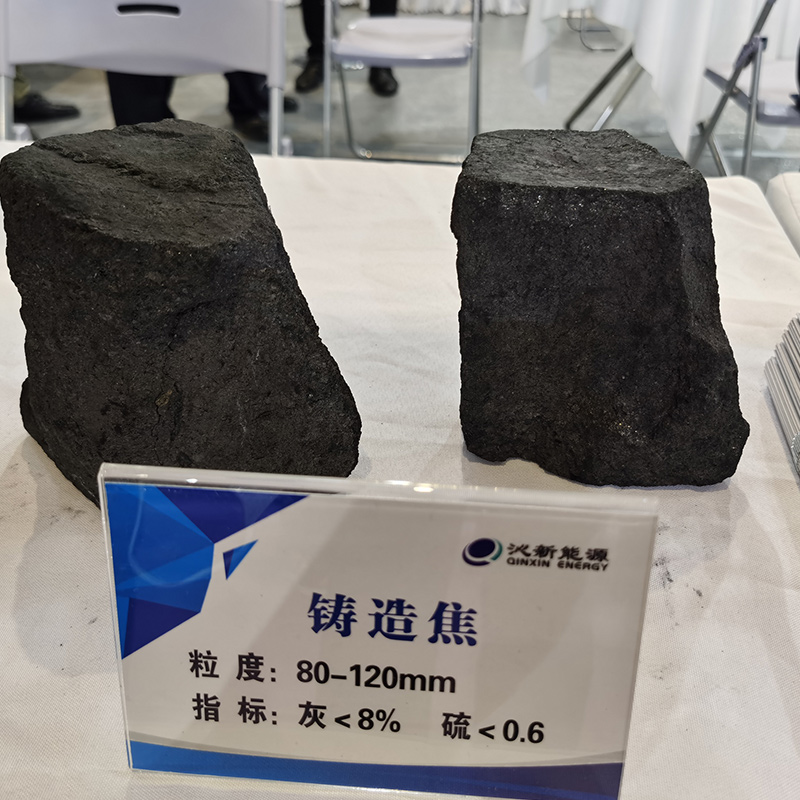

Product Description for 8% Ash 80-120mm Foundry Coke

Qinxin Foundry Coke offers high-quality foundry coke with a maximum ash content of 8%. It is known for its low sulfur and ash properties, making it ideal for precision casting. With a minimum fixed carbon content of 90%, this product ensures high efficiency during casting processes. Its low moisture content of 6% max provides stability, making it reliable for continuous use.

The foundry coke also features high abrasion resistance (90) and a compressive strength of 7, ensuring durability and reliable performance in smelting applications. It is widely used in steel metallurgy and casting, providing excellent results in demanding environments. Our product is available for export to markets in the Middle East, Southeast Asia, and South Asia, with a minimum order quantity (MOQ) of 20 tons.

Product Parameters

| Parameter | Value |

| ASH | 8% MAX |

| V, M. | 1.5% MAX |

| Fixed Carbon | 90% MIN |

| SULPHUR | 0.6% MAX |

| MOISTURE | 6% MAX |

| Type | Foundry Coke |

| Abrasion Resistance | 90 |

| Compressive Strength | 7 |

| Features | Low Ash, Low Sulfur |

| MOQ | 20 Tons |

| Applications | Steel Metallurgy |

| Main Markets | Middle East, Southeast Asia, South Asia |

Features of 8% Ash 80-120mm Foundry Coke

Large Block Size: Provides more stability and longer usage in high-temperature environments.

Low Reactivity: Reduces unnecessary reactions during the casting process, improving efficiency.

Small Porosity: Ensures better structural integrity and reduces material loss.

Adequate Compressive Strength: Offers reliable performance under high pressure in metal smelting.

Low Ash Content: Minimizes waste and impurities in the final product.

Low Sulfur Content: Helps in maintaining the quality and strength of the casted metal.

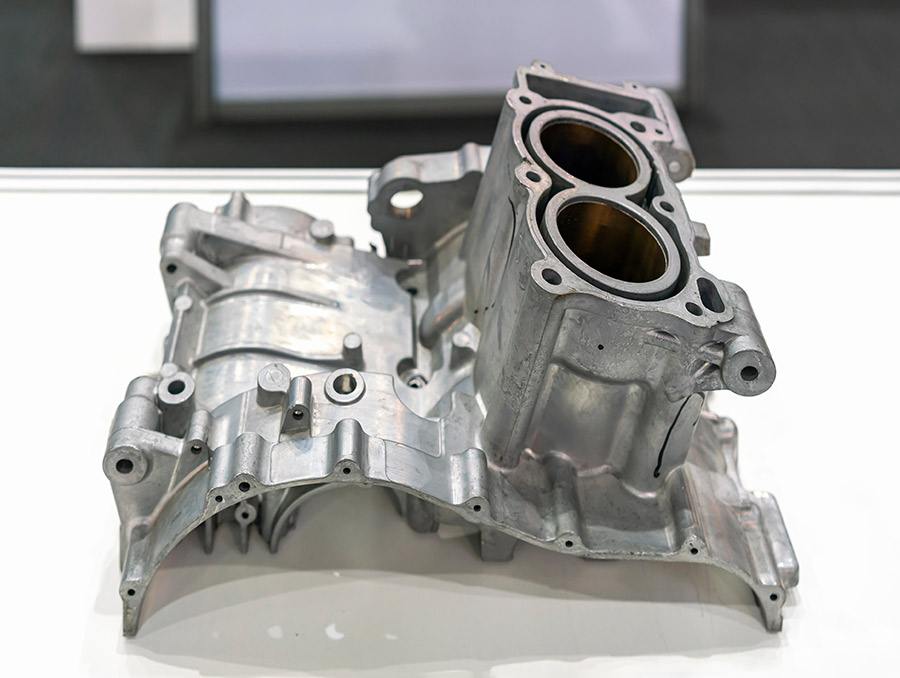

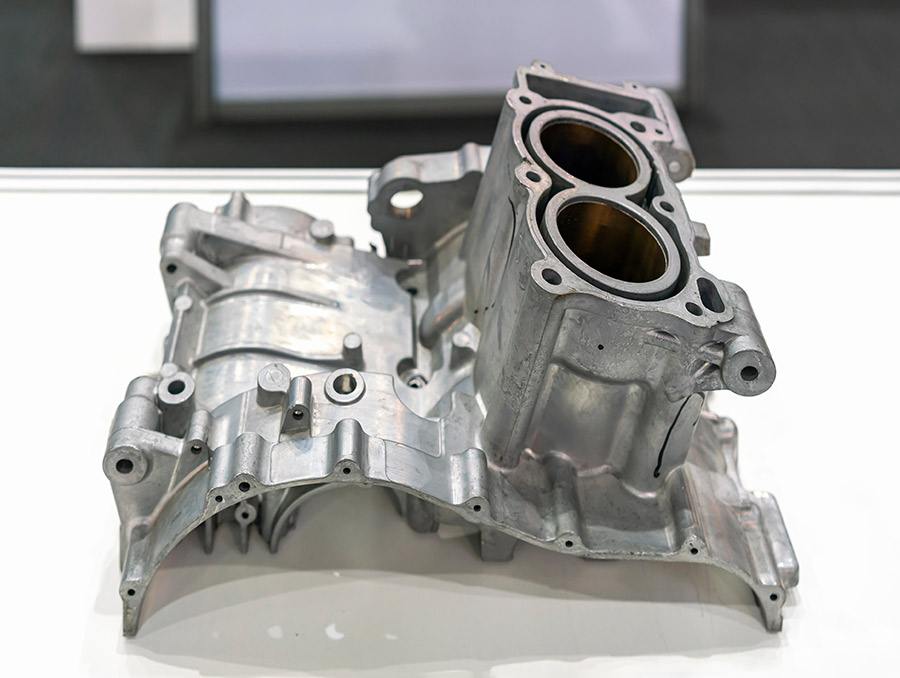

Product Applications

Services & Support

Markets: The product is successfully sold in Japan, South Korea, India, Pakistan, and Egypt, with a strong reputation.

Quality Control: The factory maintains a strict quality control system and ensures solid testing records for each batch. Third-party testing reports are available upon customer request.

FAQs

Q1: What is the maximum ash content in the 8% Ash High Carbon Hard Foundry Coke?

A1: The maximum ash content is 8%, making it ideal for precise casting and steel production processes.

Q2: What is the minimum fixed carbon content of this foundry coke?

A2: The minimum fixed carbon content is 90%, ensuring high energy efficiency during use.

Q3: What are the primary applications of this foundry coke?

A3: This coke is primarily used in blast furnaces to maintain high temperatures and ensure good permeability during the casting process.

Q4: Can this product be customized to meet specific requirements?

A4: Yes, we offer customization options for packaging and shipping based on customer specifications.

Q5: What markets do you serve with your foundry coke?

A5: Our products are widely used in markets such as Japan, South Korea, India, Pakistan, and Egypt.

Q6: How do you ensure the quality of the foundry coke?

A6: We have a strict quality control system in place and provide testing reports, including third-party verification when required.