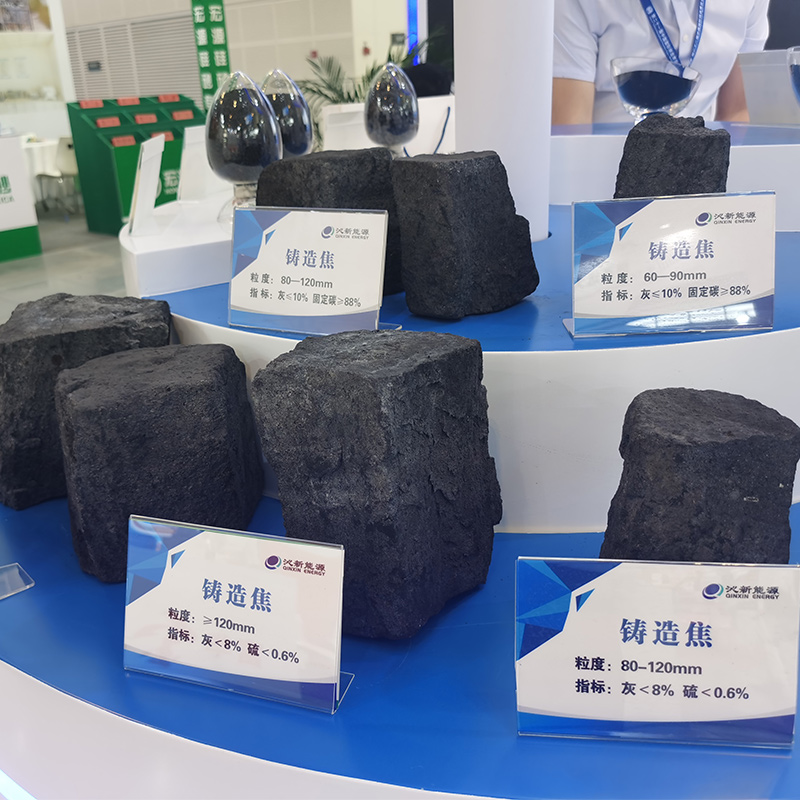

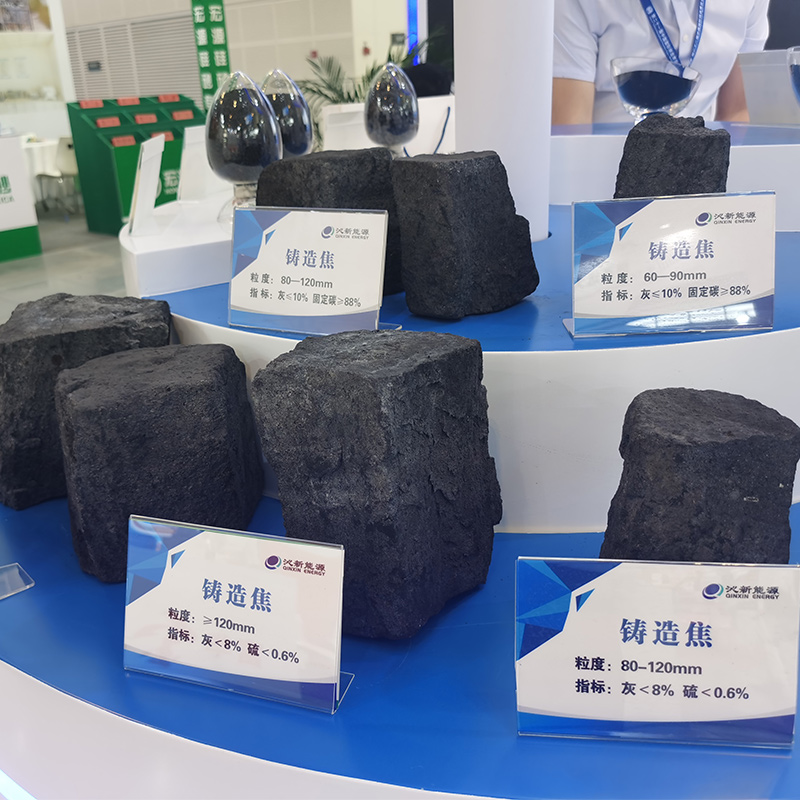

Product Description for Low Sulfur Foundry Coke

Qinxin Foundry Coke offers a premium casting foundry coke with high carbon content. This product is specially designed for casting applications, providing consistent performance.

It has a fixed carbon content of 90% minimum. The ash content is kept under 8%, ensuring minimal residue in casting processes. This foundry coke is low in sulfur (0.6% max), reducing the risk of contamination in molten metals.

The coke’s calorific value is 7300 J, ensuring efficient heat generation during the casting process. It also has high compressive strength (90), which adds durability and stability during use.

The product is available in block form with a size of 80-120mm. It offers excellent abrasion resistance (7), making it ideal for extended use in high-demand applications.

Our foundry coke comes in large packaging bags, with a minimum order quantity of 20 tons. It is the ideal solution for industries requiring high-quality, reliable foundry coke for casting operations.

Product Parameters in Table Format

| Parameter | Value |

| ASH | 8% MAX |

| V.M. | 1.5% MAX |

| Fixed Carbon | 90% MIN |

| SULPHUR | 0.6% MAX |

| MOISTURE | 6% MAX |

| Type | Foundry Coke |

| Calorific Value | 7300 J |

| Abrasion Resistance | 7 |

| Compressive Strength | 90 |

| Size | 80-120mm |

| Application | Casting |

| Packaging | Large Bags |

| MOQ | 20 tons |

| Shape | Block |

Features of Low Sulfur Casting Foundry Coke

Large block size: Provides stability and durability during the casting process.

Low activity: Ensures minimal chemical reactivity, reducing impurities in molten metal.

Small porosity: Limits the absorption of gases and liquids, improving performance.

High anti-crush strength: Maintains structural integrity under pressure, enhancing its lifespan.

Low ash and low sulfur: Reduces contamination risks, ensuring a cleaner casting process.

Special grade with ultra-low ash and sulfur: Ideal for high-quality casting applications.

Low apparent porosity: Increases efficiency and reduces wear in high-stress environments.

Product Specifications

Super Grade:

Fixed Carbon: 90%

Ash: 8% MAX

Volatiles: 1.5% MAX

Sulfur: 0.5% MAX

Moisture: 7% MAX

Phosphorus: 0.03% MAX

First Grade:

Fixed Carbon: 88%

Ash: 10% MAX

Volatiles: 1.5% MAX

Sulfur: 0.5% MAX

Moisture: 8% MAX

Phosphorus: 0.03% MAX

Second Grade:

Fixed Carbon: 86%

Ash: 12% MAX

Volatiles: 1.5% MAX

Sulfur: 0.6% MAX

Moisture: 8% MAX

Phosphorus: 0.03% MAX

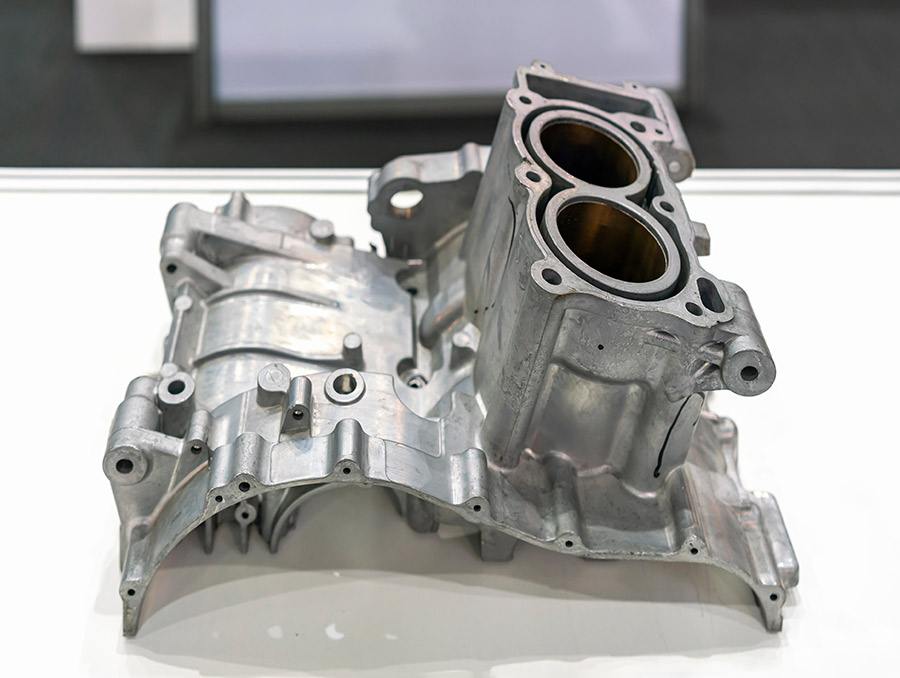

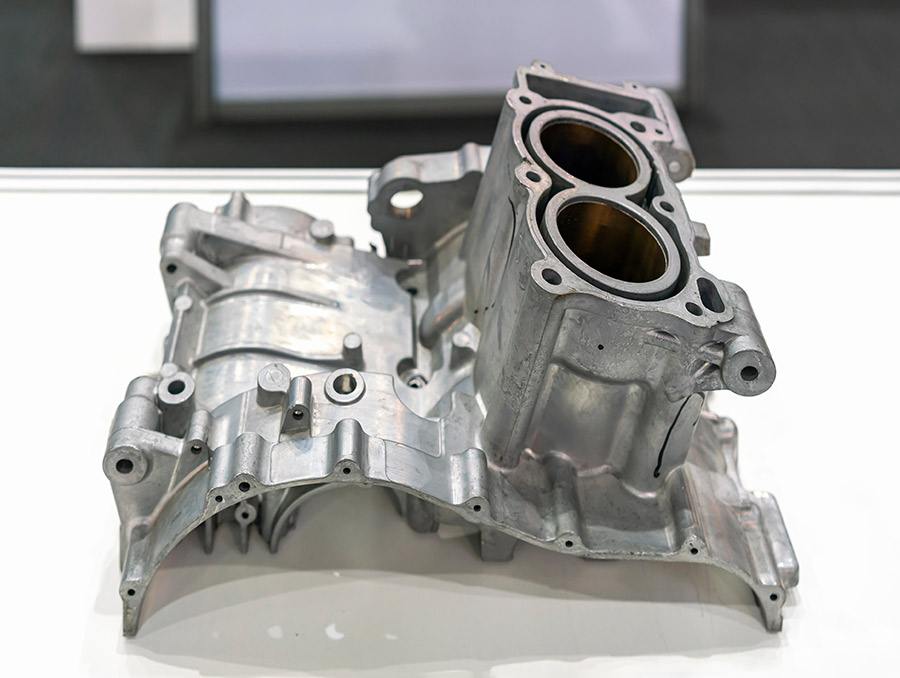

Applications

Iron melting furnaces: Primarily used to achieve high temperatures in iron melting furnaces.

Air permeability: Ensures good air permeability for better furnace performance.

Energy efficiency: Helps maintain high energy efficiency in casting processes.

Supplier Information

Company Name: Qinxin Foundry Coke

Product Range: High-carbon foundry coke, low sulfur coke, and various other metallurgical products.

Production Equipment: QRD-2000 clean heat recovery tamping coke ovens.

Design Team: Collaborates with industry experts to maintain high standards in coke production.

Company Mission: To provide stable, high-quality foundry coke with a focus on environmental protection and advanced technology.

FAQs

1. What is the main use of industrial low sulfur casting foundry coke?

Industrial low sulfur casting foundry coke is mainly used in blast furnaces for iron smelting. It helps maintain high temperatures and provides excellent permeability for better iron production.

2. What are the key features of Qinxin Foundry Coke?

Qinxin Foundry Coke is known for its high carbon content, low sulfur, low ash, and excellent crushing strength. It offers high efficiency and stable performance in casting applications.

3. What sizes are available for this foundry coke?

The sizes available for Qinxin Foundry Coke range from 80-120mm, making it suitable for a variety of industrial uses.

4. What is the sulfur content in Qinxin Foundry Coke?

Qinxin Foundry Coke contains a sulfur content of 0.6% max, ensuring low impurities during the smelting process.

5. How does Qinxin Foundry Coke benefit the casting process?

Qinxin Foundry Coke helps in reducing energy consumption and improving furnace output, ensuring high-quality metal casting with reduced operational costs.